Mr Father Eric and his brother Leslie ran a successful building contracting business for much of their working lives. As a schoolboy I used to enjoy accompanying them to various sites.

Each had their own style, but both were similar in their manner – always polite, gentlemanly and forthright. They were – and I use this phrase sincerely and as a compliment, of the old school. Their dictionary excluded both slang and swearing.

On one occasion I accompanied my uncle in his new car. I cannot recall the make of the car, but it was the speedy model, with the larger version of engine, and was much admired! We first visited a housing development in a village called Martock, after which the next stop was a similar development in nearby South Petherton. A journey between of perhaps seven or eight minutes – unless one put one’s foot down, which is exactly what he did. The new car was indeed exceedingly fast!

It is worth pointing out that this occurred before mobile phones were available.

Each site had a foreman’s site office physically connected to a landline telephone. An enormous bell fixed to the outside alerted when there was an incoming call. We arrived alongside the office in no time at all. The car was a success as far as I was concerned. The telephone bell was ringing, but as the foreman was on the far side of the development, he had not managed to answer the call. My uncle walked into the site office, picked up the receiver and listened. He immediately recognised the voice to be that of the foreman from the site we had just left. ‘The bastard’s on his way’ proclaimed the voice. My Uncle remained silent. Then, in a voice that would have impressed a BBC announcer of the period he replied: ‘The bastard has arrived!’ The foreman exclaimed an expletive and the line went dead. My Uncle grinned very slightly. ‘I’m going to enjoy this car’ he announced.

I relate this story as it leads into the subject of speeding up site progress, not by putting one’s foot down but by physically accelerating the speed of operations. One way to do so is to minimise the dependence on site fabrication work and substitute a preformed or pre-assembly approach. It is worth pointing out this has the added advantage at the same time, of also reducing exposure to the unpredictable climate of the UK.

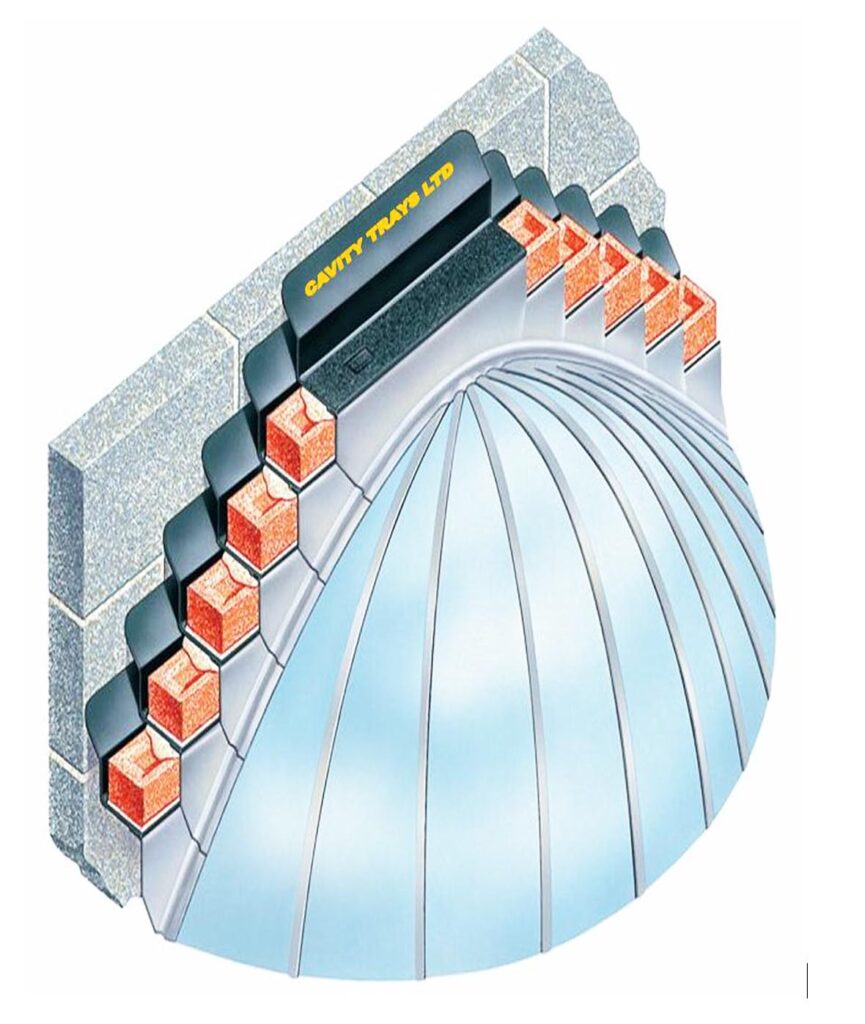

Preformed Type X Cavitrays

Preformed Type X Cavitrays

The use of preformed cavitrays can introduce a fast-track approach. They eliminate the time previously spent on site fabricating. But, and it is an important but, it is essential one chooses carefully. Some preformed components offer more advantages than others. So, if the site has a requirement for cavity trays, how might you select the right trays to ensure a requisite standard is met and at the same time speed up the build programme?

One might consider a tray that is supplied flat and requires folding to form its shape. Once this has been done this and the folded component is being held together to prevent it springing flat again, one faces the task of deciding just how to also pick up the trowel in one hand and the brick in the other? At Cavity Trays of Yeovil we supply our components ready-moulded, not flat. Every tray we supply is ready for immediate use, and is the right shape.

A typical cavity tray needs to be robust. So how thick is the material from which a tray is moulded? In a survey we discovered the thickness of material used by Cavity Trays of Yeovil was over three times thicker than that used by an alternative manufacturer. Or put it another way, the other manufacturers product was a third the thickness when compared. At Cavity Trays of Yeovil we believe a robust approach is a wise one.

Features within any tray design can make the difference between failure and success. Cavity Trays of Yeovil products incorporate water checks, gussets, integrity links, integral stopends and mortar gauging features to aid speedy installation. To what extent if any do alternatives offer any benefits?

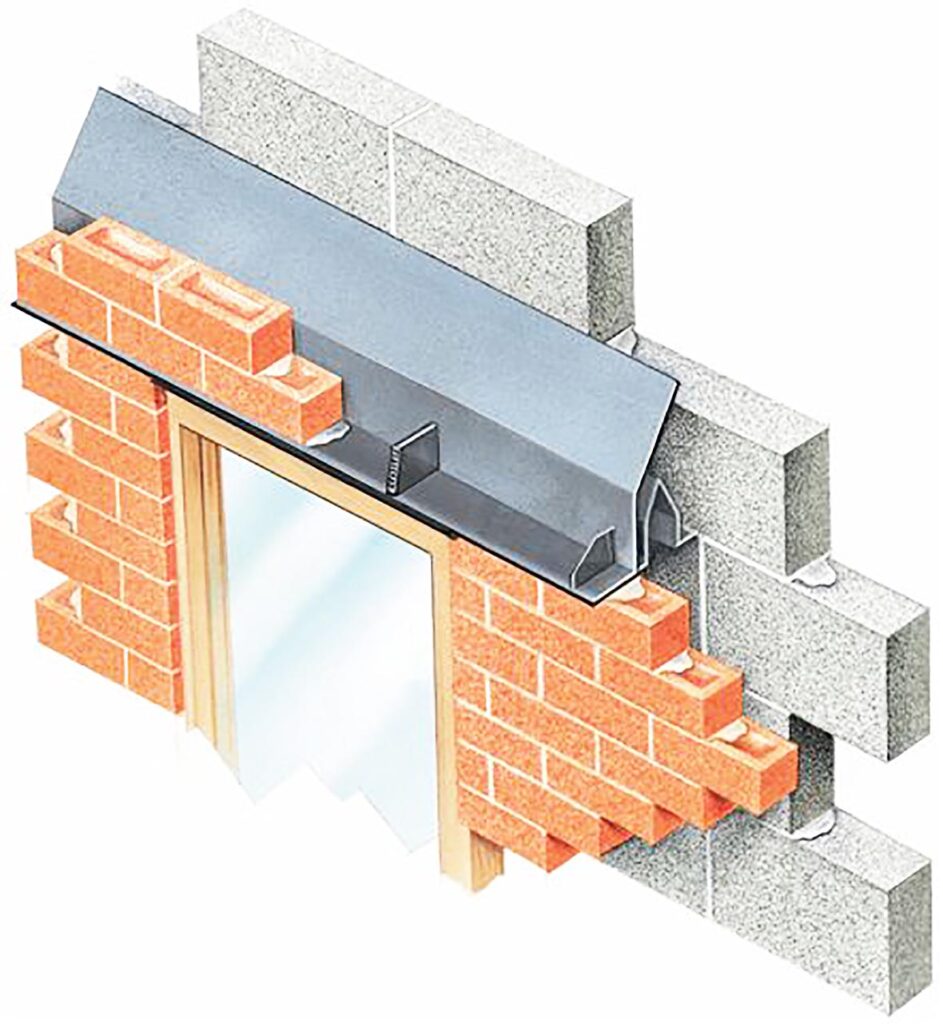

Preformed Type C Cavitary

Preformed Type C Cavitary

The predetermined cavitray profile ensures compliance and consistency. Preformed cavitrays do not sag or distort like roll DPC and the self-supporting cavity upstands have an inbuilt bias to accommodate the as-built cavity width. Alternatives with fixed-position upstands that do not adjust, cannot offer this benefit. Cavitary profiles are available to suit all opening head configurations.

Composite benefits mean the speed and ease of using a carefully selected preformed cavity tray can really fast track the build programme. But do not overlook the most essential quality. A good cavity tray establishes a consistent and defined build detail

that promotes a long service life. Cavity Trays Ltd of Yeovil is the longest-established specialist in its field and the only UK tray company awarded European Technical Approval. Additional trays have recently secured BDA certification, including non-combustible models for high-rise structures. (BAW-24-336 and BAW-24-337).

Visit our website or request literature be delivered to your door. Our Area Technical Managers will be pleased to visit you. Our approved products are accompanied with a performance warranty.