The external envelope of a building can be constructed following all the Standards, rules and good practice guidelines available, but still be problematic. Why and how can one avoid difficulties?

The original cavity tray company, Cavity Trays Ltd, has a proven track record of specialism, and provides examples of practical know-how derived over a period exceeding 100 years.

On the basis optimum performance of a cavity wall exists when the wall is dry, returning it to dry status following saturation is the objective. BS EN ISO 15927-3-2009 is a British Standard reporting on hourly weather observations, although they are not referenced in UK Building Regulations. The Standard qualifies a weather spell period as the time rain water exceeds the loss due to evaporation. Interestingly it qualifies it can take as long as 96 hours with no rain, before evaporation loss exceeds the gain from the rain – even if the rainfall lasts only in excess of one hour.

At what speed rain travels over a wall surface and permeates a wall is influenced by many factors. The surface finish, the material, the module dimensions, the extent of perimeter mortar, the mortar composition itself and the style of pointing. An important accompanying caveat always is the quality or workmanship.

When rain saturates an external skin, the penetrating water will gravitate down through the walling material and on its cavity face, and it will track across connections between external skin and inner skin.

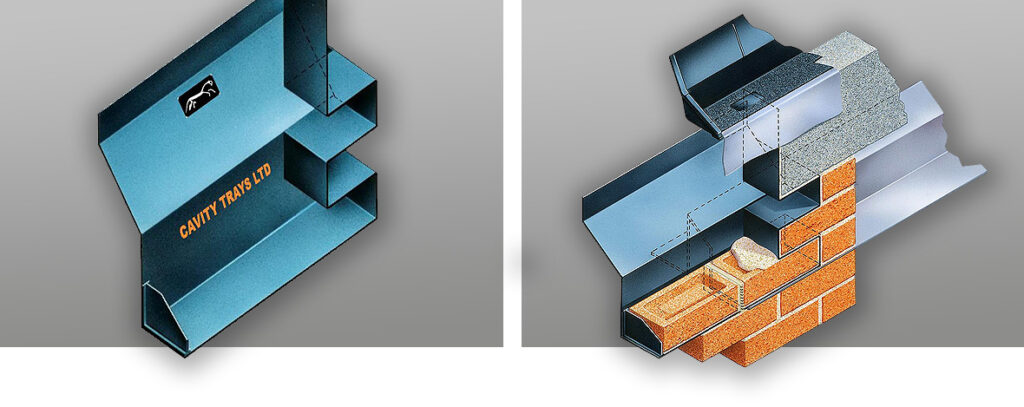

Example of a preformed tray designed to integrate with two protective elements, each at a different level, with brickwork bonding and DPC continuance.

Example of a preformed tray designed to integrate with two protective elements, each at a different level, with brickwork bonding and DPC continuance.

Wall ties are shaped to oblige such water to drip off the ties and not reach the inner skin. Lintels, DPC’s and trays are angled so water is deflected outwardly towards the exterior leaf. All very straightforward until one adheres to the current PD 6697 6.2.7.7.8 that states the DPC can step inwardly or outwardly. The reference is made to cavity parapet walls and if followed, a parapet wall upon saturation can feed permeating water inwardly on the underside to the inward step. However, fortunately alternative approaches exist that circumvent this problem.

External walls are often rendered and a rendered wall can reduce rain permeation of the exterior skin, but rendering does not prevent it. Over the projected life of a rendered external skin, movement cracks and fissures will appear, but even before so doing, wet will soak through and once behind the render coat, will gravitate within the outer skin and down the cavity face of the outer skin. If differing material types exist within a rendered elevation, (such as sills, quoins, corbels) differing absorption /wet transference rates and expansion/contraction rates will come into play in addition.

Gravitating water flow within an on an external skin will be interrupted wherever the cavity is bridged by a window or door opening. With stopends at the end of the DPC arrangement over each opening, such water pools within what effectively is a trough – one side of which is porous (masonry). The water has no free-flow exit routes, unless weeps are incorporated, but PD 6697 states under section 6.2.7.7.3 that ‘weepholes need not be provided if walls have a rendered finish’. Without weeps external damp banding from the horizontal water reservoir behind the render coat can eventually manifest – not always, much depends to what extent the elevation is exposed. If water s retained, staining will follow, and in freezing conditions spalling initated. Alternative approaches can avoid such a situation.

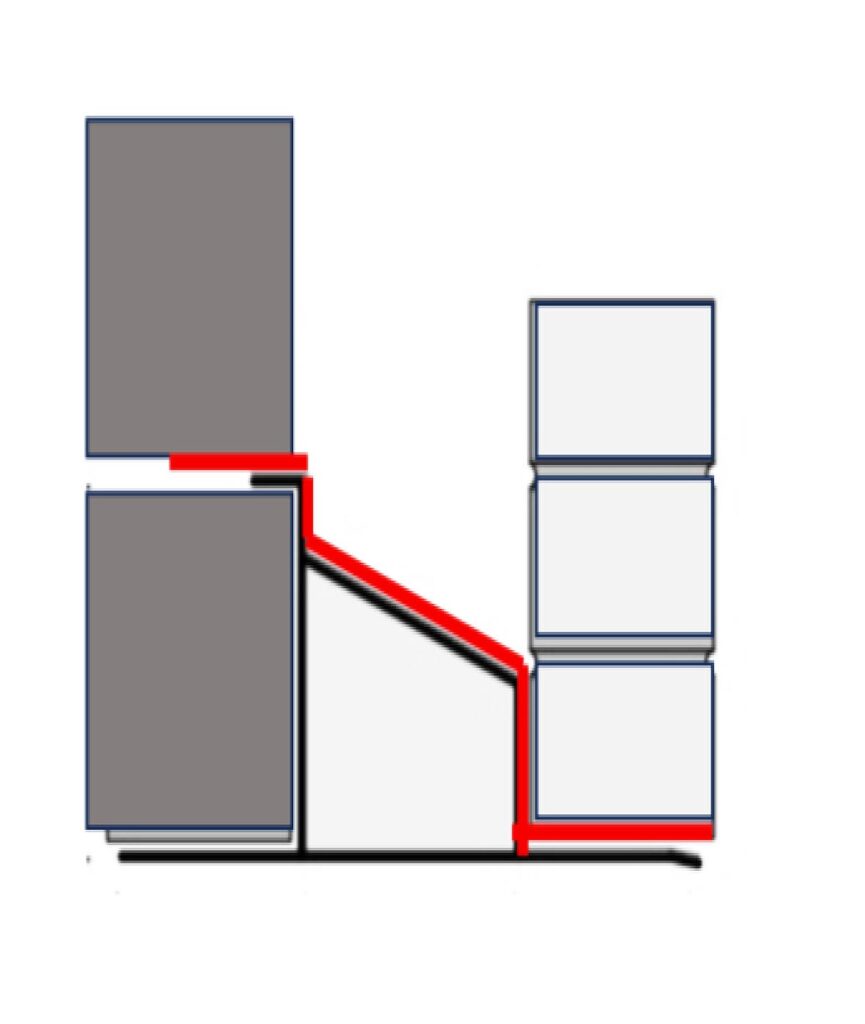

DPC not rising to NHBC height?

DPC not rising to NHBC height?

On the subject of openings within cavity walls, some lintels are illustrated with an accompanying DPC laid against / following the lintel profile, but doing so with lintels of limited rise results in the arrangement falling short of mandatory dimension requirements. For example, the NHBC requires 140mm minimum rise of which the upper 100mm is clear.

Again, there are ways to avoid unintentionally defaulting the stipulated rise dimension, one being by using a preformed cavity tray with a compliant transversing upstand that is self-supporting. By so doing incorrect protection dimensions cannot arise. Additionally, a preformed tray can also have an external protective lip as per NHBC 6.1.17, and extended ends permit optional offset water evacuation via discreet Caviweeps that are designed to guard against contra pressure inflow from direct wind and rain – acknowledging the UK weather extremes are changing.

This brings us back to the absorption behaviour of the walling medium and its surface finish. Both smooth and textured surfaces alter water travel behaviour. The pressure and direction at which wind-driven rain strikes a wall is also relevant. Rarely constant, with periodic gusts, rain can transverse an external surface until wind pressure and water volumes are overcome by gravity. Where wind-driven rain is experienced for prolonged periods, there is little opportunity for a masonry skin to dry through evaporation.

Discreet hooded weeps or specialist caviweeps with integral baffles guard against wind-driven water wash entering the structure, an aspect that can adversely impinge when winds exceed 45mph (250 Pa – BS 4315-2).

The objective always is to construct an external envelope that minimizes water inflow and controls all permeation in a manner that returns the external skin to dry status as swiftly as possible. With 100 years of specialism at your service embracing technical, digital and practical building envelope construction solutions, Cavity Trays Ltd is at your service with a team of dedicated specialists. We welcome talking with you.